Release time:2024-11-11 16:35:40 browse:

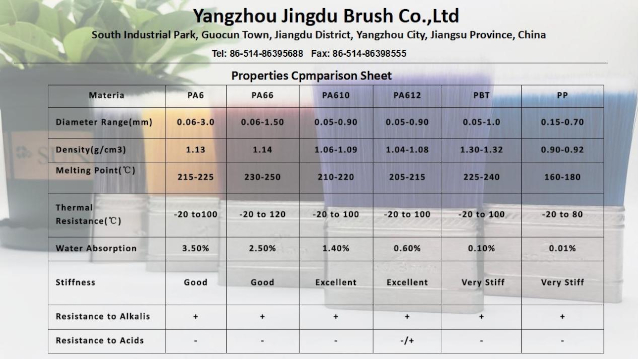

1. Basic Composition: PBT monofilaments consist mainly of polybutylene terephthalate, with a typical density ranging from 1.3-1.4 g/cm³ and a melting point of 220-230°C.

2. Characteristics Overview: These monofilaments are noted for their robust strength, high elasticity, excellent fatigue and solvent resistance, and their alkali sensitivity, which makes them particularly effective for tapered filaments in various brushes.

3. Tapered Filament Process: Made through a process known as melt spinning, these filaments are engineered with precision-tapered tips, commonly used in high-detail brushes.

4. Physical Properties: PBT, a sturdy polyester, contains structural elements like benzene rings and ester groups, making it tougher than many similar materials, such as nylon.

5. Fiber Performance: PBT fibers offer high tensile strength and elastic modulus, superior heat setting capabilities, and low moisture absorption, ideal for challenging environments.

6. Versatility and Utility: Thanks to its low water absorption, PBT remains rigid in humid conditions, serving as an efficient alternative to materials like Nylon 66, with enhanced abrasion resistance.

7. Market Price Trends: The pricing of PBT is currently stable, indicating a balanced demand and supply in the brush manufacturing market.

8. Comparative Material Study: PBT demonstrates superior durability and cost-efficiency compared to other polymers like PP and PET, according to latest market comparisons.

9. Applications in Brush Making: PBT is extensively used in the paintbrush industry due to its adaptability, chemical resistance, and longevity, making brushes more efficient and durable.